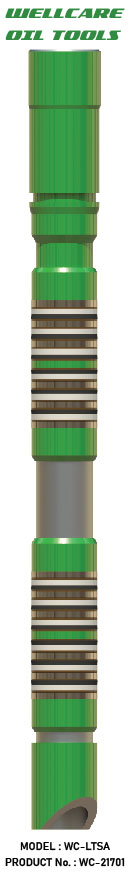

LOCATOR TUBING SEAL ASSEMBLY

- WC-LTSA / WC-21701

Locator Tubing Seal Assembly is designed for limiting downward movement of the seals in the packer bore. Normally landed with the tubing in compression sufficient to prevent seal movement upward. Any number of seal units can be added for increased length. Standard assembly includes two seal units.

Locator Seal Assembly is designed for hostile environments, high temperatures and high pressures.

It is made up of metal parts that meet the requirements of NACE standard MR-0175 for sulfide stress cracking resistant materials and is suitable for use in H2S environments. This locator also be used in noncorrosive environments where pressure and temperature requirement warrants.

FEATURES & BENEFITS

The standard Seal System consists of three set of seals (bonded, chevron, A-ryte, V-ryte etc) and debris barriers. The seals are arranged so that they are protected by the debris barriers in the event of tubing movement. The two lower debris barriers and two lower seal stacks are the main working seals and should never be allowed to leave the seal bore. The upper debris barrier and seal stack are a back-up and also prevent settings from entering the bore, which could lead to sticking or seal damage.

Available Size

2.668 INCH

To

4.750 INCH

* For Specification guide please refer Specification Sheet supply with each Product.